The age of automation has descended upon us. The advent of technologies like artificial intelligence (AI) and internet-of-things (IoT) has completely altered the way we manufacture things. This transformation has been so revolutionary that it is being dubbed the fourth industrial revolution or Industry 4.0.

When computers were introduced during Industry 3.0, they disrupted and changed the way we did everything. Industry 4.0 builds upon the developments of Industry 3.0 but takes it another step further. Computers can communicate and interact with the physical world in ways never seen before, allowing them to make decisions with or without human involvement.

Cyber-physical systems exploit the improved capabilities of computers to create new ways of production and value creation. An example of such a solution would be robotic arms equipped with computer vision capabilities, to streamline and increase effectiveness across manufacturing lines today. This forms the basis of Industry 4.0 and enables the transformation of traditional manufacturing firms into smart factories.

Taking a closer look at ASEAN

Based on a McKinsey report, ASEAN is predicted to capture productivity gains of up to US$627 billion. Industry 4.0 represents a golden opportunity for ASEAN nations to grow their industries and boost productivity. With a strong manufacturing foundation alongside a growing and dynamic domestic market, the ASEAN region is well-poised to take advantage of Industry 4.0.

Business leaders in the manufacturing space are also very hopeful about the future of Industry 4.0. Over 90% of business leaders expect that new technologies brought about by Industry 4.0 will bring about improved performance and boost revenues. Governments are also on-board and have shown great excitement about the potential of Industry 4.0.

Countries are hoping that Industry 4.0 can pave the way to either revitalize or boost the growth of their manufacturing sector. Through the implementation of new manufacturing technologies, countries are looking to boost national productivity and provide more jobs for their people. To harness the full potential of the fourth industrial revolution, most of the ASEAN countries have issued national strategy plans specifically targeted at Industry 4.0. To supply the demand for innovation, start-ups become an indispensable part of that equation.

These plans vary greatly between the different countries due to socio-economic factors as well as the development of existing infrastructure. They range from more broad-based strategies like Singapore’s Industry Transformation Map that targets more than 20 industries to more targeted strategies like Indonesia 4.0 which only targets 5 industries. Despite the diversity, every country prioritizes infrastructure building, attracting new investors, and driving innovation as key initiatives to cash in on Industry 4.0.

Among the diverse strategies, Singapore’s strategy stands out as one of the most proactive and ambitious. Innovation has always been the key to Singapore’s success, with Singapore being ranked third in the Bloomberg Innovation Index. This innovation streak has also made its way into the manufacturing space.

How Singapore is riding the wave

Being one of the world’s leading financial hubs, you might assume that Singapore might not have a future in the manufacturing space. This is far from the truth. On the contrary, Singapore has quietly risen to become one of the top global exporters of high-tech products and its journey to consolidate its position as the world’s leading industrial hub does not seem to be stopping anytime soon.

Today, Singapore has established itself as a key player in sectors such as aerospace, electronics, biomedical sciences, and precision engineering. This has attracted industry giants like Micron and Shell to invest and partner with Singapore in the research and development of the latest technologies.

According to the World Economic Forum’s Readiness for the Future of Production Report 2018, Singapore was ranked second in the world in being best positioned to benefit from the changing nature of production. With the advent of Industry 4.0, Singapore has doubled down on its efforts and fully embraced the new movement. Singapore is aiming to grow its manufacturing sector by 50 percent over the next 10 years and continues to position itself as one of the most attractive prospects for start-ups. Let’s go from a macro to micro perspective on why you might want to consider Singapore:

- Strong government support

Singapore stands out from its peers when it comes to the sheer amount of funding and support for the Industry 4.0 movement. In most countries that are leading forces in the field of Industry 4.0, government support is an imperative component in the early stages of adoption.

Heeding this advice, Singapore has invested heavily in not only R&D but also the wider Industry 4.0 ecosystem. Singapore has invested S$3.2 billion in Advanced Manufacturing and Engineering domains between 2016 and 2020. This investment is targeted towards bolstering the innovation capacity of companies embracing Industry 4.0. Looking forward to 2025, Singapore has laid out strategic plans to continue its transformation into a global digital manufacturing hub.

This provides companies with the flexibility and the capability to explore the burgeoning start-up ecosystem for tailor-made solutions to their problems. This initiative creates a collaborative environment for start-ups and corporations to research and test-bed solutions before deploying them.

- Innovative start-up ecosystem

Since 2014, Singapore has achieved the top rank in the Asia Pacific region on the Global Innovation Index. Singapore has an exceptionally dynamic innovation ecosystem with the presence of both private and public supporting organizations.

Organizations such as EDB and Enterprise SG provide schemes and grants to major corporations and start-ups alike to boost their innovation capability. Well-established global companies like Softbank and Intel have also chosen to populate the innovation ecosystem with their corporate venture capitals.

This amalgamation of private and public organizations creates an environment that is ripe for start-ups to innovate and develop. This allowed Singapore to be ranked amongst the top 5 ecosystems for start-ups in Asia according to the Global Startup Ecosystem Report (GSER) 2021. Over 36,000 start-ups have chosen to locate themselves in Singapore and that number has been steadily growing as the scene becomes more and more established.

The thriving start-up ecosystem alongside the well-established manufacturing sector has led to a rise of start-ups focusing on developing Industry 4.0 solutions. One of such notable start-ups is Structo, a 3D printing solution provider focused on dentistry, which raised over $3 million. It is my firm belief that with continued support from the government, the number of successful start-ups focusing on making Industry 4.0 a reality will continue to increase.

- A strong culture of corporate start-up partnerships

Across the ASEAN landscape, many manufacturing corporations are struggling with Industry 4.0 adoption. One of the key strategies to deal with this challenge is to partner up with innovative start-ups and accelerate the entire process. Manufacturers are looking towards start-ups to co-innovate and develop tailor-made solutions.

Strong government support and a growing start-up scene positions Singapore as one of the key providers of this solution. Many leading manufacturers have begun exploring Singapore’s start-up and SME ecosystem for such solutions. For instance, when German semiconductor manufacturer giant Infineon was looking for a solution for the transport of materials across its production floor, it discovered Hope Technik, a Singaporean SME. The partnership was highly successful and was named the “Most Disruptive Collaboration between an SME and a Multinational Company” at the 2017 Singapore International Chamber of Commerce Awards.

- Regional Innovation Hub

To further support the Industry 4.0 ecosystem in Singapore, the Jurong Innovation District was planned and developed. It functions as a home to a wide range of players along the entire industrial value chain. One of the key centerpieces of the district as well as this movement is the Advanced Remanufacturing and Technology Centre (ARTC).

ARTC is Asia’s first manufacturing innovation center to embrace and push the idea of the public-private partnership model to its full potential and drive innovation in the manufacturing space. ARTC has strong partnerships with over 80 consortium member companies, including members like Rolls-Royce. This creates endless opportunities for industrial collaboration. Since its establishment in 2012, it has completed over 555 industry-funded projects.

ARTC collaborations do not only stop at leading players in the industrial space, but it also represents an avenue for start-ups to get into the fray. One of its key initiatives is the A*STAR Advanced Manufacturing Startup Challenge. Through the crowdsourcing of ideas from start-ups, it can provide an access point for start-ups to collaborate with well-established industrial partners while solving key industry pain points. This win-win initiative functions as a key opening for start-ups to break into the Industry 4.0 market and establish themselves as one of the key players in this space.

With the recent launch of the Southeast Asia Manufacturing Alliance (SMA), Singapore will become an avenue for start-ups to break into the entire Industry 4.0 ecosystem in the SEA region. The SMA creates a playing field for Singapore companies to engage global partners and gain a foothold in the region. This provides a unique value proposition where start-ups can be nurtured in the Singapore ecosystem while being able to have the opportunity to explore the entire SEA landscape once they have developed.

The Next Manufacturing Frontier

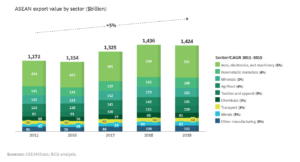

As the movement of Industry 4.0 continues to evolve and gain traction, it has the potential to revolutionize and revitalize ASEAN manufacturing. With ASEAN’s five largest manufacturing industries poised to gain huge benefits from Industry 4.0 technologies, it becomes a question of not if but when ASEAN becomes one of the key manufacturing hubs of the world.

Amongst the various countries that make up the ASEAN region, it is my firm belief that Singapore has positioned itself to be one of the best avenues to join the Industry 4.0 movement. With a dynamic innovation ecosystem that is built upon strong government support and diverse industry partners, Singapore has created an unparalleled platform for start-ups to transform new and innovative ideas into products used on the factory floor.